When you consider slicing-edge technology in production, on the list of 1st things which most likely concerns intellect is definitely the laser cutting equipment. These extraordinary devices are revolutionizing how industries tactic precision and performance. Whether or not It is really for creating intricate designs or just slicing by means of challenging elements, a laser cutter can manage it all easily. The magic of laser reducing technological innovation lies in its power to offer you large precision and versatility. Visualize a laser cutter as a higher-tech sculptor, carving out styles With all the precision of a talented artisan.

Laser cutters, or CNC laser cutting machines, are particularly notable for his or her exacting requirements. Contrary to standard cutting techniques which can be imprecise and labor-intensive, CNC laser chopping automates the procedure, reducing human mistake and expanding productiveness. This technological innovation makes use of Personal computer numerical Handle (CNC) to guideline the laser, making certain that every Slash is executed specifically as prepared. It is really akin to using a robotic that has a ruler, making sure every element within your style and design is ideal.

Not known Details About Laser Cutting Equipment

Industrial laser slicing has produced significant strides through the years, evolving from standard designs to remarkably innovative methods able to managing a number of products. Industrial purposes range from automotive components to aerospace parts. The versatility of industrial laser cutters would make them indispensable in many sectors. Think about them as the Swiss Military knives from the producing environment—adaptable and indispensable.

Industrial laser slicing has produced significant strides through the years, evolving from standard designs to remarkably innovative methods able to managing a number of products. Industrial purposes range from automotive components to aerospace parts. The versatility of industrial laser cutters would make them indispensable in many sectors. Think about them as the Swiss Military knives from the producing environment—adaptable and indispensable.Probably the most intriguing aspects of laser slicing technology is its precision. Whenever we speak about precision laser slicing, we're referring to the power of such machines to achieve amazingly limited tolerances. As an example, some laser cutters can generate components with tolerances as restricted as 0.1 mm. This amount of precision is crucial for industries where by each millimeter counts, which include in electronics or health-related machine producing. It is really like drawing which has a pencil that under no circumstances wavers from the road.

The Of Precision Laser Cutting

The products used in laser reducing programs could be rather advanced, nonetheless it’s the Superior features that make them so highly effective. Fashionable laser slicing equipment frequently incorporates subtle cooling techniques, high-driven lasers, and automated loading and unloading mechanisms. These capabilities contribute into the device's efficiency and longevity, guaranteeing that companies get quite possibly the most out of their investment. Envision a properly-oiled equipment that’s always all set to carry out at its greatest—that’s what large-quality laser slicing machines provides.

The products used in laser reducing programs could be rather advanced, nonetheless it’s the Superior features that make them so highly effective. Fashionable laser slicing equipment frequently incorporates subtle cooling techniques, high-driven lasers, and automated loading and unloading mechanisms. These capabilities contribute into the device's efficiency and longevity, guaranteeing that companies get quite possibly the most out of their investment. Envision a properly-oiled equipment that’s always all set to carry out at its greatest—that’s what large-quality laser slicing machines provides.For anyone inside the sheet steel marketplace, a sheet metallic laser cutter can be a recreation-changer. Traditional ways of cutting steel sheets is often cumbersome and imprecise, but laser cutters excel With this area. They offer clean up cuts and intricate patterns without the need to have for additional finishing. This not just speeds up creation explore now but also enhances the general top quality in the completed product. Image a sculptor with a high-quality-tuned chisel—This is often how laser cutters function with sheet metallic.

Laser reducing products and services have gotten increasingly well-liked for companies planning to outsource their cutting needs. These providers offer you entry to Highly developed laser reducing technological innovation without the need for sizeable upfront investment. It’s like renting a luxury auto for on a daily basis—you have to enjoy the benefits click for details without the extended-time period dedication. These companies can manage all the things from compact prototype runs to substantial output batches, producing them a versatile Answer for many industries.

Whenever we go over laser chopping programs, we’re referring towards the detailed set up that features the laser cutter by itself, Command programs, and sometimes software for building and controlling cuts. These systems are created to operate seamlessly jointly to make higher-quality success. Think about it as a well-orchestrated symphony where each and every portion performs a vital function in obtaining the final masterpiece. The integration of those elements is essential to maximizing efficiency and precision.

Precision in laser slicing isn’t pretty much precision; it’s also about regularity. Laser chopping equipment retain the same degree of precision throughout each Slice, ensuring that each component is just like the last. This consistency is vital for industries wherever uniformity is important, such as in manufacturing elements for electronics or automotive areas. It’s like possessing a meticulous craftsman who under no circumstances misses a conquer.

The Ultimate Guide To Laser Cutting Equipment

With regard to technological developments, laser reducing carries on to evolve. New developments in laser reducing technological know-how are building these equipment quicker, far more effective, and able to dealing with all the more advanced jobs. Innovations which include fiber lasers and hybrid methods are pushing the boundaries of what’s feasible. It’s like upgrading from a smartphone to a reducing-edge system with features you didn’t even know you wanted.Laser reducing tools may be quite an financial investment, nevertheless the return on investment decision (ROI) is commonly significant. The effectiveness, precision, and decreased squander linked to laser reducing suggest that companies can see substantial Expense financial savings after some time. It’s a tiny bit like investing in a large-excellent Software that saves you effort and time In the long term. The First expenditure could be offset with the gains in efficiency and high quality.

Getting My Laser Cutting Machine To Work

For industries that have to have intricate models and substantial levels of customization, laser chopping technologies is really a aspiration appear real. A chance to make complicated designs and in depth parts devoid of sacrificing high-quality is really a match-changer. No matter if you’re planning custom made parts for machinery or crafting intricate decorative elements, laser cutters offer unparalleled overall flexibility and precision.

The environmental advantages of laser cutting can also be value noting. Due to the fact laser cutting is so precise, it typically ends in considerably less product squander in comparison to classic reducing methods. This precision not just will help in lowering expenses and also minimizes the environmental influence. It’s like employing a laser scalpel rather than a blunt knife—far more successful and less wasteful.

In conclusion, laser slicing devices and technological know-how signify a big development in manufacturing and Laser Cutting Systems design. Irrespective of whether you’re taking a look at industrial laser chopping, CNC laser slicing, or specialized sheet metallic purposes, the advantages are apparent. With precision, efficiency, and flexibility, laser cutters are paving the way in which for the way forward for creation. So following time you marvel at a superbly crafted component or even a wonderfully intended piece, remember there’s a very good prospect a laser cutter built it attainable.

Luke Perry Then & Now!

Luke Perry Then & Now! Rick Moranis Then & Now!

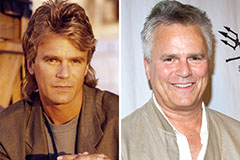

Rick Moranis Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!